Products developed for our customers in the categoryof Canulas, Drug Implantation Systems and Trocars

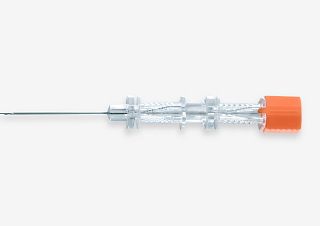

Epidural Needle

Requirement

Production of a strong needle that requires less penetration force.

Solution

sfm has developed a strong and functional epidural needle for use in local anesthesia. Special attention was paid to the tactile feel of the hub and wing in order to increase the level of control during penetration. The smooth transition from the hub to the needle makes it easier to insert the catheter. The bevel eye is deburred to protect the catheter.

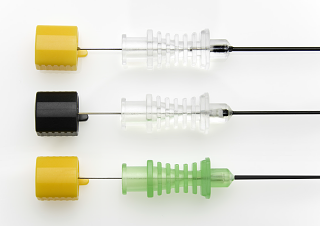

Spinal Needles

Requirement

Develop an extremely thin needle with an atraumatic tip for use in local or spinal anesthesia.

Solution

The special geometry of the needle tip provides greater strength and stability for penetration of the dura mater. At the same time, the matching Pencil-Point or Quincke bevel reduces post-spinal headache.

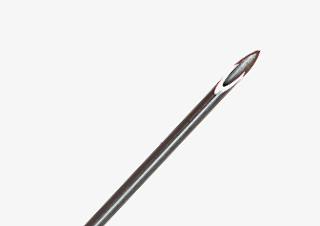

Radiofrequency (RF) Needles

Requirement

Develop a medically approved coating for RF needles that has both heat resistant and electrical isolation properties.

Solution

sfm was able to develop a RF needle with a safe, electrical isolation coating. In addition, the smooth casing allows nearly pain-free penetration and navigation through the patient’s tissue.

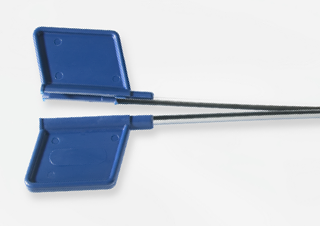

Stimulation Needles

Requirement

A perfect connection between needle, tubing and connection cable to prevent the escape of fluids.

Solution

Our extensive knowledge of metal and plastics processing makes it possible to equip a stimulation needle with an external plastic casing that perfectly unites the needle, tube and connection cable.

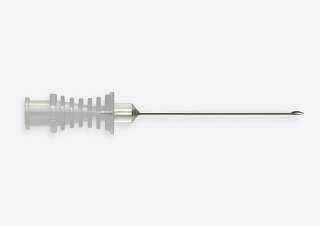

Seldinger Needle

Requirement

Optimization of the bevel geometry and 100% lumen control to improve the use and safety of the needle in cardiac and angiographic procedures.

Solution

Through a silicone coating and deburring of the bevel eye, substantially less force is required during puncture. The improved bevel geometry prevents punching a hole during tissue penetration. 100% lumen control allows optimum passage of the catheter.

Split Needle

Requirement

An easy to split and strong metal needle for suprapubic bladder puncture.

Solution

The particularly safe, reliable and user-friendly design is the hallmark of the sfm split needle. The silicon coating facilitates penetration. The treatment is less painful for the patient and the risk of infection is substantially decreased.

Channel Needle

Requirement

A customer commissioned us to produce a strong needle with a slot along its entire length. In order to prevent the catheter from being damaged during removal, the needle must be deburred and treated accordingly.

Solution

sfm developed an easy-to-use needle for suprapubic bladder access. The catheter is easy to extract after placement due to the needle’s long, rounded-edge slot. The special silicone coating facilitates penetration and reduces any pain felt by the patient.

Veterinary Needles

Requirement

Develop a multifunctional applicator for safe, subcutaneous implantation of animal identification chips.

Solution

The needle’s applicator is manufactured in such a way that the transponder chips for animal identification can be inserted while maintaining sterility. The special facetted bevel geometry and silicone coating of the needle reduce the pain felt by the animal during insertion.

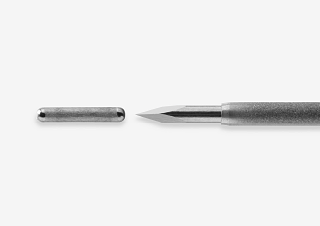

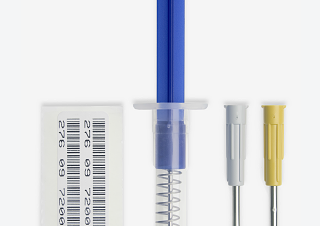

Implantation Needles

Requirement

Develop a special trocar needle for Bayer HealthCare AG for implantation of a depot drug.

Solution

A special plunger was developed for easy deposit of the implant under the skin. The ergonomic design of the needle hub, as well as the special bevel geometry and markings, simplifies the needle's use.

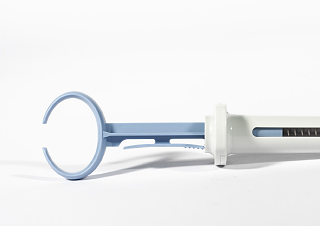

Applicator / Application System

Requirement

Develop and manufacture an applicator needle and applicator as an aid for implantation of a depot drug.

Solution

The ergonomically designed applicator simplifies the deposit of the implant. A special safeguard prevents accidental release of the implant deposit and ensures secure placement. The implantation is fast, simple and minimally invasive for the patient.